The Ultimate Guide To Welders Near Me

Wiki Article

Our Welders Near Me Diaries

Table of ContentsOur Welding Table StatementsThe Buzz on Underwater Welding7 Simple Techniques For Welding TableSpot Welder Can Be Fun For AnyoneSome Known Details About Smaw An Unbiased View of Spot WelderSmaw for Beginners

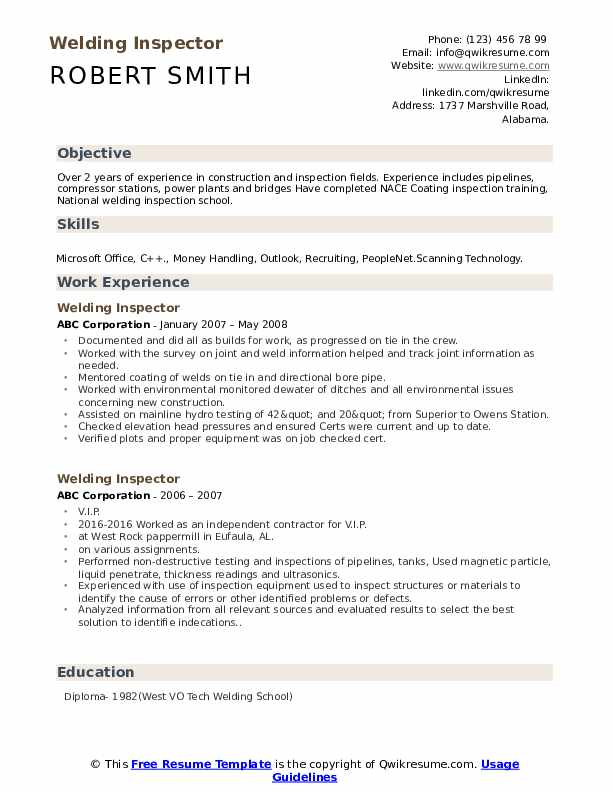

Assessors measure bonded items to make certain that they fulfill requirements for measurement. The licensed weld assessor makes use of stress and anxiety devices to put anxiety on weld joints.Assessors likewise check weld device arrangement and the welding techniques of welders on operate in progress to ensure the quality of the job. Welding examiners tape the results of tests as well as welding evaluations. Certifications, Companies may call for a senior high school education and learning for a qualified welder placement. A college education and learning is not needed for a lot of welding or welding inspection placements, yet an associate degree in welding innovation can boost the chances of landing a task.

Automation does not lower the demand for evaluation.

Something went wrong. Wait a minute and try again Attempt once again.

What Does Spot Welder Mean?

Senior Personnel Designer, National Board This article was initially published in the Fall 2009 National Board BULLETIN as the initial of a two-part collection. Please see Basic Weld Assessment - Component 2 for the verdict of this article. Keep in mind: The objective of this article is to provide inspectors with a basic knowledge of weld evaluation.While not important, the examiner should find out to read typical weld icons such as the AWS signs. At the minimum, the inspector must always bring a reference guide to analyze weld signs. Having actually examined all this info ahead of time, the inspector will certainly be prepared to identify any kind of troubles as they create as opposed to after-the-fact.

The supplier or repair service company (certification owner) has shown on duty drawing that a weld joint is to be prepared with a 60-degree bevel as well as origin gap of 1/16 inch. Unless the bevels are grated on accuracy machinery, it is skeptical they will certainly attain a specific 60-degree bevel as shown.

The nozzle axis is 90 to the level head, and also the accessory weld consists of a 3/8-inch fillet weld. The examiner can conveniently gauge the fillet weld to guarantee conformity.

Not known Details About Mig Welder

This example comes to be even more important if the nozzle is installed at an angle apart from 90 (Fig. 3). Using the very same nozzle add-on instance as explained above, let's check out the weld joint prep work. The certificate holder has defined a 45-degree bevel around the area of the opening in the level head and the vessel covering.4). The bent covering will provide even more of a difficulty. The inspector will need to identify if the certificate holder is referencing the bevel from the upright axis of the nozzle (Fig. 5) or from the variable referral aircraft of the rounded shell (Fig. 6). When bevels are prepared with a reducing torch as well as ended up with a mill, it is extremely hard to maintain a specific angle.

Just how does the inspector ensure conformity with the code? Assessors are educated to believe only what their eyes inform them; however click when the inspector can not see the inner surface area of television, it becomes challenging to accept that scenario. This is when the assessor has to take what some would call a "leap of faith." If the tube ends are appropriately prepared (beveled) and a certified welder is utilizing a certified welding treatment, the chances are very excellent that the welds will be complete infiltration.

One "warning" to a possible issue would certainly be if the examiner observes that television ends have actually not been beveled. The examiner should instantly ask the certificate holder concerning this situation. It might be as simple as the certificate owner having simply not performed that action in the process yet, or it can be as poor as his or her having attempted to conserve time as well as money by not beveling the ends.

The 45-Second Trick For Cold Welding

The welder would certainly require to begin with a large origin gap and after that be very mindful not to "press with" excess filler steel to trigger weld accumulation on the within of television.1, clause 6. 1, calls for welding examiners of all levels to pass an eye exam, with or without rehabilitative lenses, to confirm near vision skill, in at the very least one eye, on Jaeger J2 letters or smaller sized at a range not much less than 12 inches. A color perception test and also a comparison differentiation shades of grey test should be taken, but the company develops the acceptance for these 2 tests based upon the weld examination being carried out.

I keep in mind functioning for a supervisor that was around as cocky and also arrogant as they come. He dealt with almost everyone he consulted with derision. He would certainly simply been promoted to supervisor and also was attempting to be a ruffian. We were working with a rather high high-rise, his first "huge task." That's where "Mr.

He informed the examiner he required to hurry and also leave our means similarly a drill sergeant would certainly tell a new recruit to obtain down and also do push-ups! The examiner didn't claim a word; he simply nodded as well as strolled off. The next morning when we reached the task there was a sea of red throughout the flooring we were functioning on.

Our welding inspector was not a pleased camper. The good news is for us, we were able to talk to the inspector and also explain what a moron our boss was and that he was not speaking for our crew.

Not known Details About Smaw

Impact examination. Etching. Devastating are generally made use of in academic testing, store screening, as well as examinations welders require to obtain accredited or hired on at a jobsite.The duties are divided into 3 find out this here main stages; Verify that the product remains in conformity with drawing/ WPS determined as well as mapped to a test certificate in appropriate problem (cost-free from damage and also contamination) WPS is approved and also available to welders (and examiners). Welding tools is in suitable problem and also adjusted as suitable.

Recognition of welders qualification for every WPS to be used and all welder certification certifications stand. Welding consumables to be made use of are-as defined by the WPS-stored/controlled as defined by the QC treatment. Joint fit-ups are in accordance with WPS/ drawings Tack welds serve per criteria, code or WPS.

Guarantee climate conditions are suitable/ conform with Code (problems will certainly not affect welding) when on-site/ area welding. Welding process should be in accordance with WPS.

Some Known Incorrect Statements About Smaw

Ensure all reports/records are completed as well as collected as required. 1 Program note.Report this wiki page